IT Asset Tracking for Manufacturing

Track hardware, software, and IT equipment across your organization — designed for Manufacturing teams.

Why Manufacturing teams need this

Modern manufacturing floors blend operational technology (OT) with IT — shop floor workstations running MES software, HMI panels on production lines, barcode scanners at quality inspection stations, tablets used by floor supervisors, and PCs in engineering offices. These devices operate in environments with dust, vibration, and temperature extremes that accelerate wear.

Shop floor IT devices degrade faster due to dust, vibration, and temperature exposure, but lifecycle tracking is rarely done

The IT/OT convergence means networked production devices must be inventoried for cybersecurity compliance frameworks

Multi-shift operations and floor staff turnover make it difficult to maintain accurate device assignment records

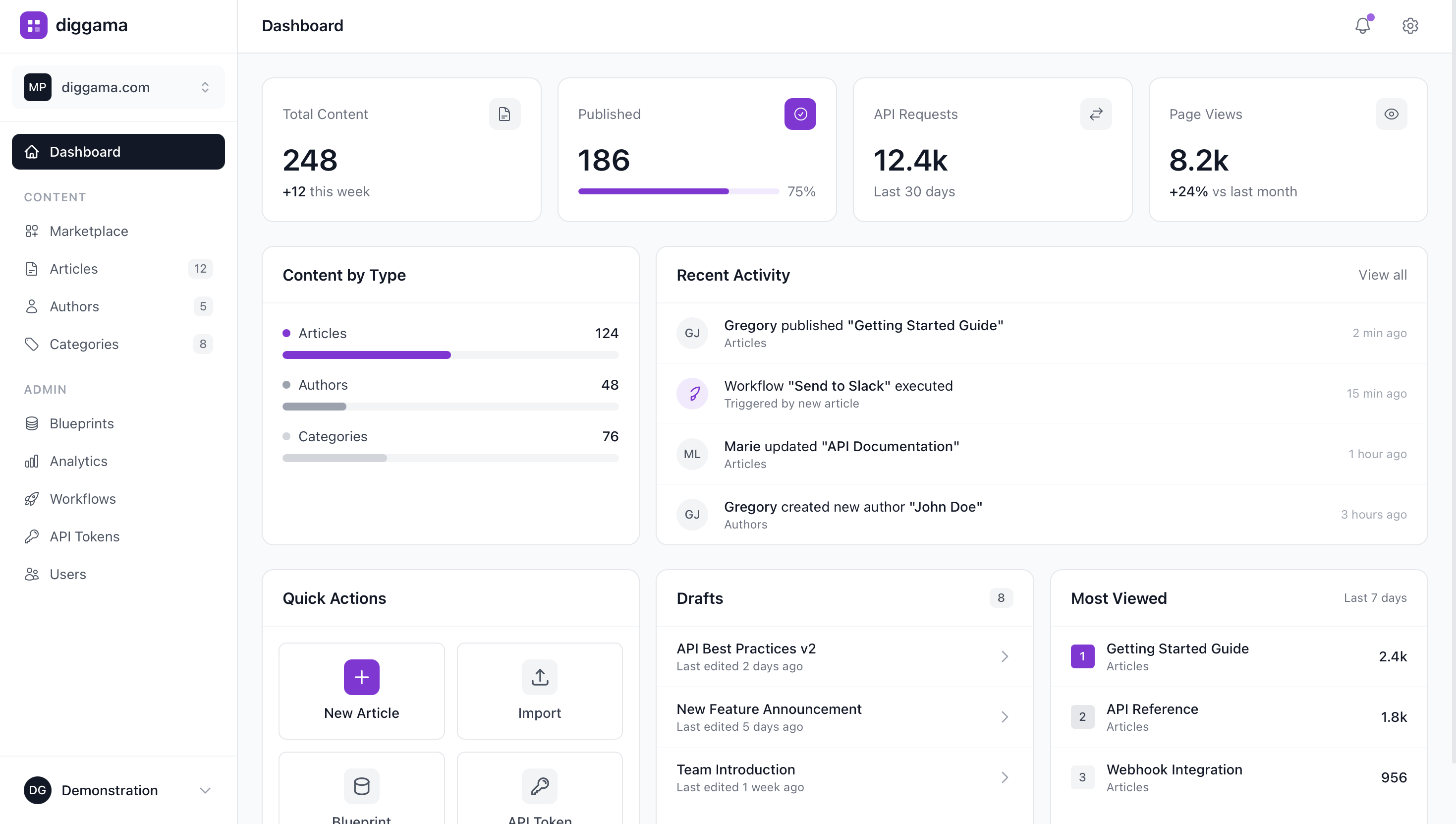

What Manufacturing teams gain

Maintain a unified inventory of both IT and OT devices across production lines and office environments

Support cybersecurity compliance frameworks by documenting all networked devices with their network status

Track device condition and age in shop floor environments to plan replacements before failures disrupt production

Improve IT budget accuracy with lifecycle data that reflects actual manufacturing environment wear patterns

Real-World

Example

A mid-sized food packaging manufacturer with 2 production lines and 85 IT/OT devices — including 20 HMI panels, 30 shop floor workstations, and various scanners — had no unified inventory. When a cybersecurity consultant flagged the gap during an IEC 62443 readiness assessment, the plant IT manager built a device registry on a structured platform. Each device was cataloged by type, location (line, station, office), network status, and age. The team discovered 11 devices running end-of-life operating systems and prioritized their replacement. Annual IT budget planning improved because replacement forecasts were now based on actual device condition data rather than estimates.

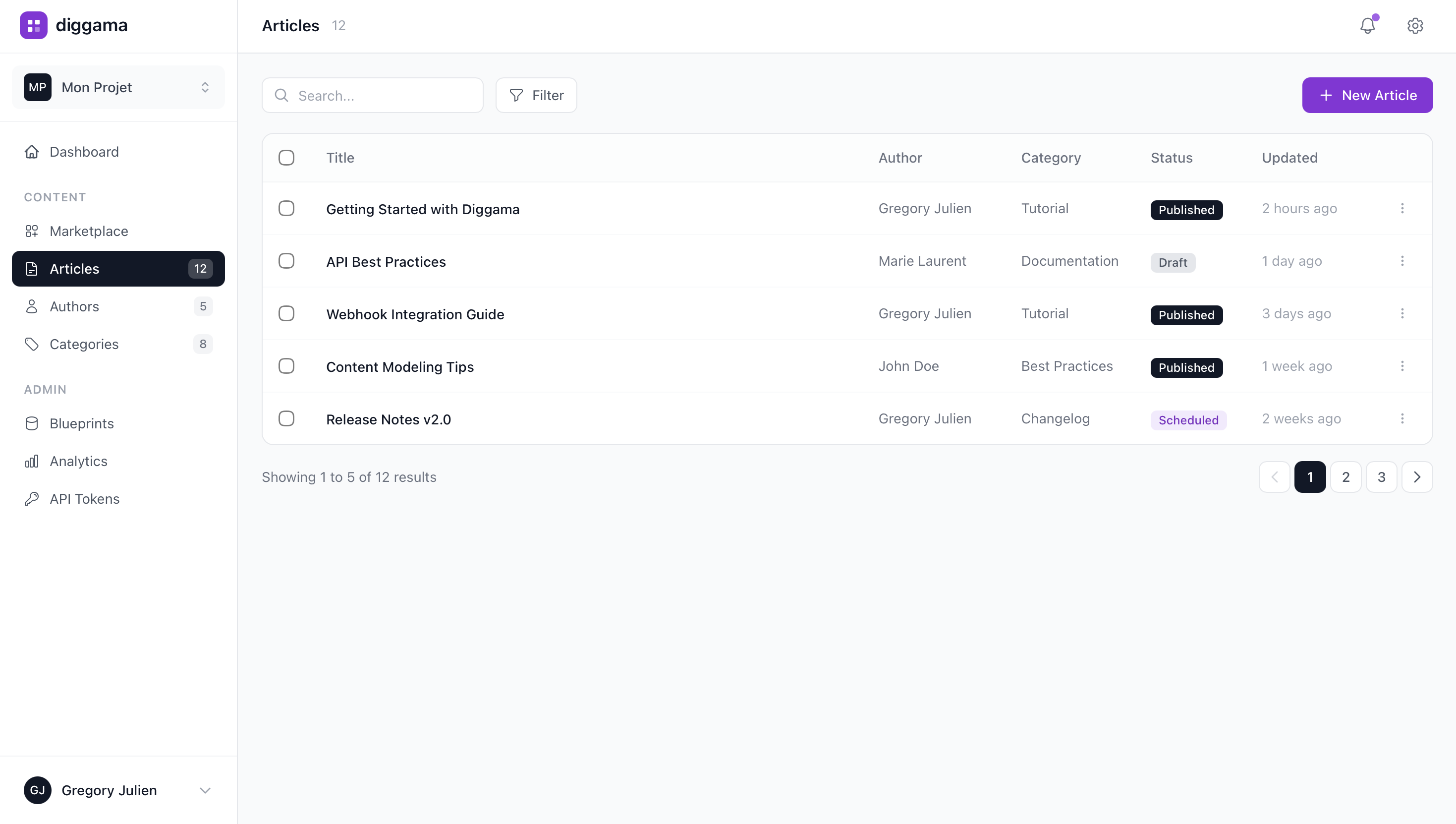

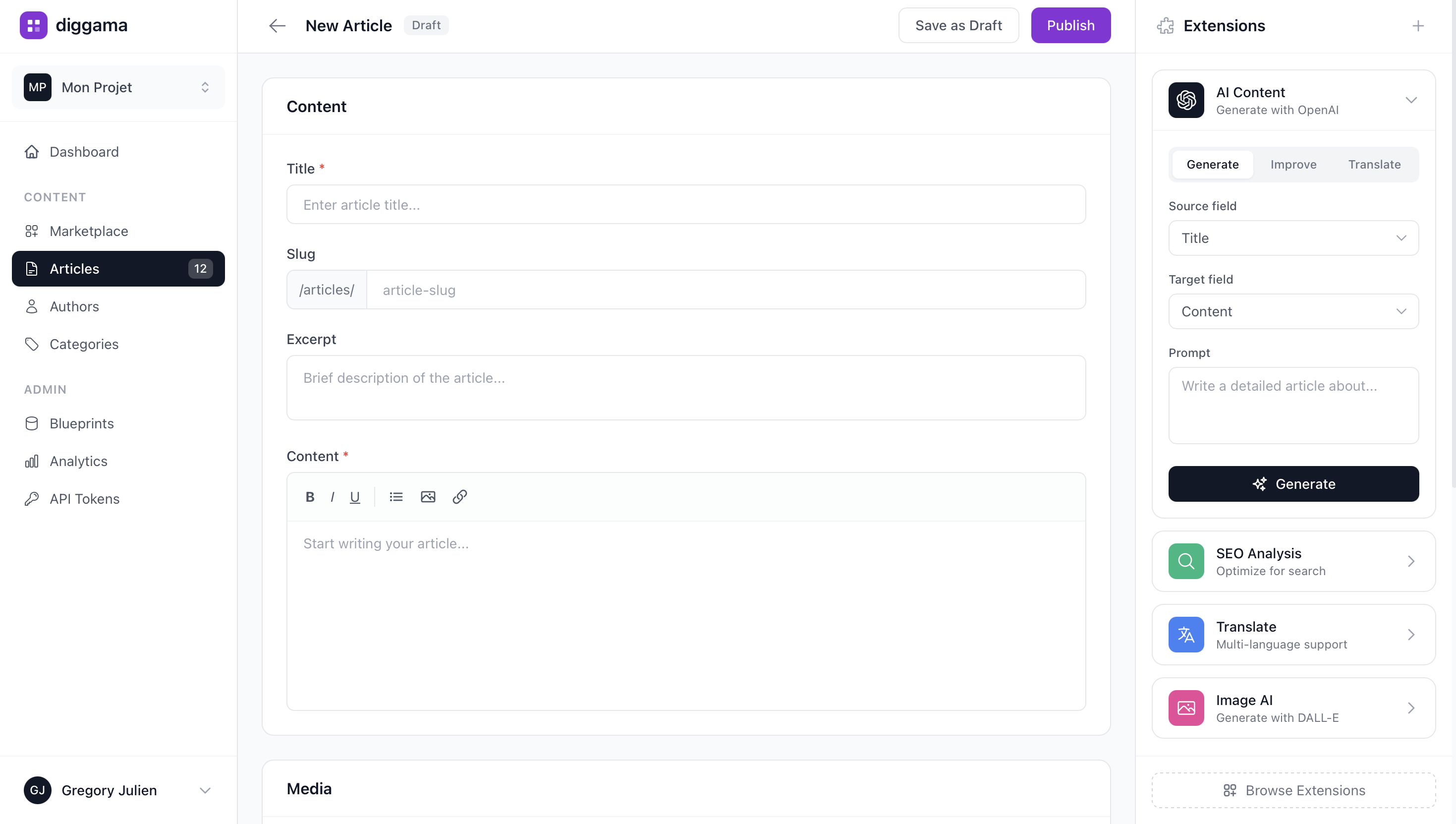

Features for Manufacturing

Frequently Asked Questions

Is Diggama IT Asset Tracking suitable for Manufacturing?

What are the key benefits for Manufacturing?

Does Diggama handle Manufacturing compliance requirements?

What features matter most for Manufacturing?

How much does Diggama cost?

How long does it take to set up?

IT Asset Tracking built for Manufacturing

See how Manufacturing teams use Diggama. Start free today.